Company

The Hiebler company in Stainz:

Full-service provider in plastics technology since 1985

The Hiebler company has been a versatile complete provider in the fields of plastics technology, multi-component production and injection moulding as well as tool and mould making since 1985. The variety of services we offer makes us a competent partner for companies, private customers and inventors, covering the entire spectrum. We accompany our customers from the idea and product development, through construction and design, to the finished product.

40 years of experience in plastic injection moulding have made us a specialist in multi-component technology. We find solutions for your products with different plastics or plastic-metal combinations.

Our modern machinery includes over 26 injection moulding machines (horizontal and vertical) with a clamping force of 50 to 800 tonnes and shot weights of 1 to 2000 grams, as well as fully automated production islands. This allows us to produce individually according to your wishes.

As an innovative, experienced company in mould and tool making, we offer our customers services from all areas of mould making. Take advantage of our technical possibilities and our capacity for your productivity.

Customer service has a particularly high priority at Richard Hiebler.

Visit our company profile on FirmenABC.at!

The future has been ‘moulded’ here for over 40 years!

The Hiebler company developed from a one-man operation into one of the leading companies in the plastics industry in Austria.

1985 - The founding year: The company was founded on 11 November 1985. At that time, Richard Hiebler mainly carried out repairs and modifications to ski boot moulds with just one employee. Soon afterwards, the company began manufacturing new ski boot moulds. In the following years, 2-component ski tips were also produced for the ski industry, among other things.

1994: The production of ski boot moulds was discontinued and plastic production was expanded at the same time. New employees were employed and trained accordingly. The production range of plastic parts was expanded. The Hiebler company gradually developed into an impressive production facility for injection moulded parts.

2000: Thanks to several years of experience in the 2-component injection moulding process, the company was able to gain a foothold in the automotive industry and win Audi as a customer. The production of metal-plastic combinations finally expanded the range of services.

2005: The expansion of the business premises was successfully completed. In October, the company moved into the new warehouse and the new office building.

2006: An insolvent company in Lebring was acquired, increasing the number of machines from 16 to 23. The two production facilities also enabled the product range to be expanded.

2008: The company was merged with the Lebring production facility at the main site in Stainz. The competitiveness of the plant in Stainz was strengthened with 23 injection moulding machines. The production halls and the office building cover a total area of approx. 1,600 m². In 2007, around 50 employees worked in 3-shift operation.

2015: 30 years of Hiebler - we celebrated and thanked our employees, customers and suppliers for the many years of partnership and cooperation. We currently produce for our customers with over 90 employees in 3-shift operation.

Richard Hiebler

Management

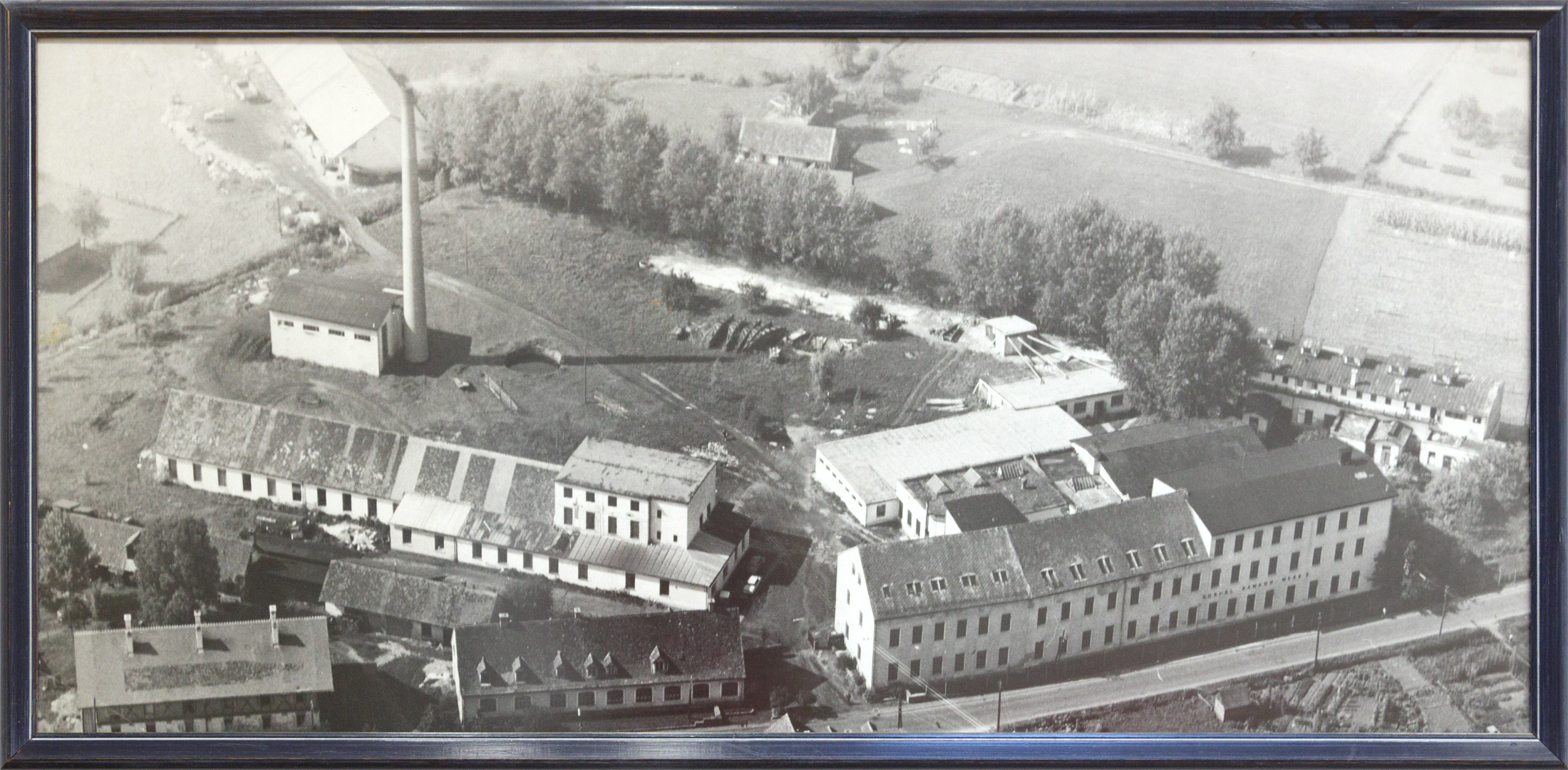

Historical view from 1964 of the current factory premises.

Co-operations

Kunststoffcluster

www.kunststoff-cluster.at

Association of Austrian Plastics Processors

www.kunststoff.or.at

F&E:

Thanks to our focus on product development and innovation, we are currently in talks with a number of universities and research institutes about long-term collaborations.